Our Pool House Controller systems are designed to be simple, intuitive and straightforward to use, even for clients who don’t like computers. Whilst the system is built on established powerful computerised process controllers and the latest technology, the user needs no special skills to operate it. The design is clear, simple, bright and uncluttered.

All user interfaces are simply provided by LCD colour touch screens. One of these is located inside the Pool Plant Room on the controller cabinet, and is the Master controller at the heart of the system. It provides access to the more technical functions required to maintain and fine-tune the operation of the complete system.

There are one or more Slave stations as required, which are intended for pool users. These would usually be located in and around the Pool House, but because they only require an Ethernet IP link to the Master controller they can be mounted anywhere you want them. For example in a large private house or small leisure club installation, the Pool House may be located away from the main building. In this case there would be a Master controller in the Plant Room, one beside the pool in the Pool House, and maybe another in the the main house or building.

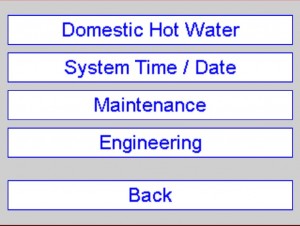

At the Slave stations, the compact LCD colour touch screen provides full control and programming of the following systems via a straightforward menu system:

- Pool House interior heating operating times and temperature.

- Pool House interior domestic hot water operating time and temperature.

- Main Pool Temperature.

- Spa Temperature.

- Quick access to additional Spa controls such as hydrotherapy jets, air blower, and lights via convenient buttons.

- Fully waterproof housing to IP65.

- Access to settings limited by pass codes as required.

In the Pool House Plant Room the Master Controller will provide all the above features, plus additional functionality required for maintenance and system set-up:

- Setting individual pool status as decommissioned (modifies Pool House controller menus), during maintenance or Winter shut-down for outdoor pools.

- Operation of Boiler, individual pumps, valves, for maintenance purposes.

- Boiler temperature control for optimum efficiency.

- Fine tuning of system operating temperatures and other parameters.

- Full internet-based remote management and monitoring of Pool House controls (note that this requires provision of Internet access by Ethernet, and configuration of the Internet router for secure access).

- Powerful PC-based software can remotely monitor and operate all controllers in the system, on multiple installations simultaneously.

- Ability to read the set and actual Spa and main pool temperatures on the display screens, over the internet, and by optional SMS Text.

- Fully Automatic Frost protection in Pool House and Plant Room, by monitoring Pool House, Plant Room, and external temperatures.

- Battery backup of configuration and setting data in the event of power failure.

- Safe programmed start-up after power failure.

- Status monitoring of the Boiler and circulation systems, and pool pumps.

Additional functionality required for maintenance and detailed system set-up will not be available at Slave stations. This is intended to secure the system configuration from accidental modification. Any system changes can be prevented by use of a simple access code, which can be activated if desired.

The menu has different levels off access locked depending on the user

The sophisticated Industrial-quality Programmable Logic Controllers (PLC) at the heart of the system offers many opportunities for increased functionality and expansion. It is also designed to be capable of networking with other similar controllers (e.g. main house building control) if desired, using the Ethernet IP network for communication.

Safety is paramount, and the system provides Fail-safe operation, with Fault Tolerance. in the event of a filtration pump failure, safe shut-down of related equipment (such as UV Sterilisers and Chlorinators) is automatic.

Any of the following features may be added either at the time of installation or at a later date, although they obviously have cost implications. They are presented here to give options, and an idea of what is possible:

- Monitoring of oil tank levels (requires additional sensors and controller outstation with Ethernet link located by the oil tanks) to facilitate refuelling, or Boiler shut-down when the fuel level is too low.

- Activation of auxiliary electrical heating for frost prevention, for example in the event of an oil-fired Boiler running out of fuel.

- SMS text status enquiry, control, and alerts (e.g. read or set pool/Spa temperature).

- E-mail notification of significant events requiring attention (e.g. Boiler failed to fire, low fuel oil levels, etc.).

- Integration with similar controls in the main house if required in future.

- Integration with lighting systems in the Pool House.

- Biometric fingerprint scanner to secure system from unintended changes.

- Integration of Solar and Heat Pump heating sources.

- Vacuum monitoring on pool drain to shut down pump and sound alarm if drain is blocked.

- Integration into controls of moving floor systems